How Long Does It Take for a Shoe Factory to Make a Sample? Unveiling the Timeline and Key Factors

In the footwear industry, a shoe sample (or "prototype") is the core link between design and mass production. The aesthetics of a shoe’s shape, its wearing comfort, and the efficiency of mass production all depend on the precision of sample making. So, how long does it take for a shoe factory to make a sample? As an enterprise focusing on mid-to-high-end footwear, we’ll break down this process based on years of OEM/ODM experience.

I. The Core Process of Sample Making

Sample making is a meticulous process of "turning drawings into physical products," mainly including the following steps:

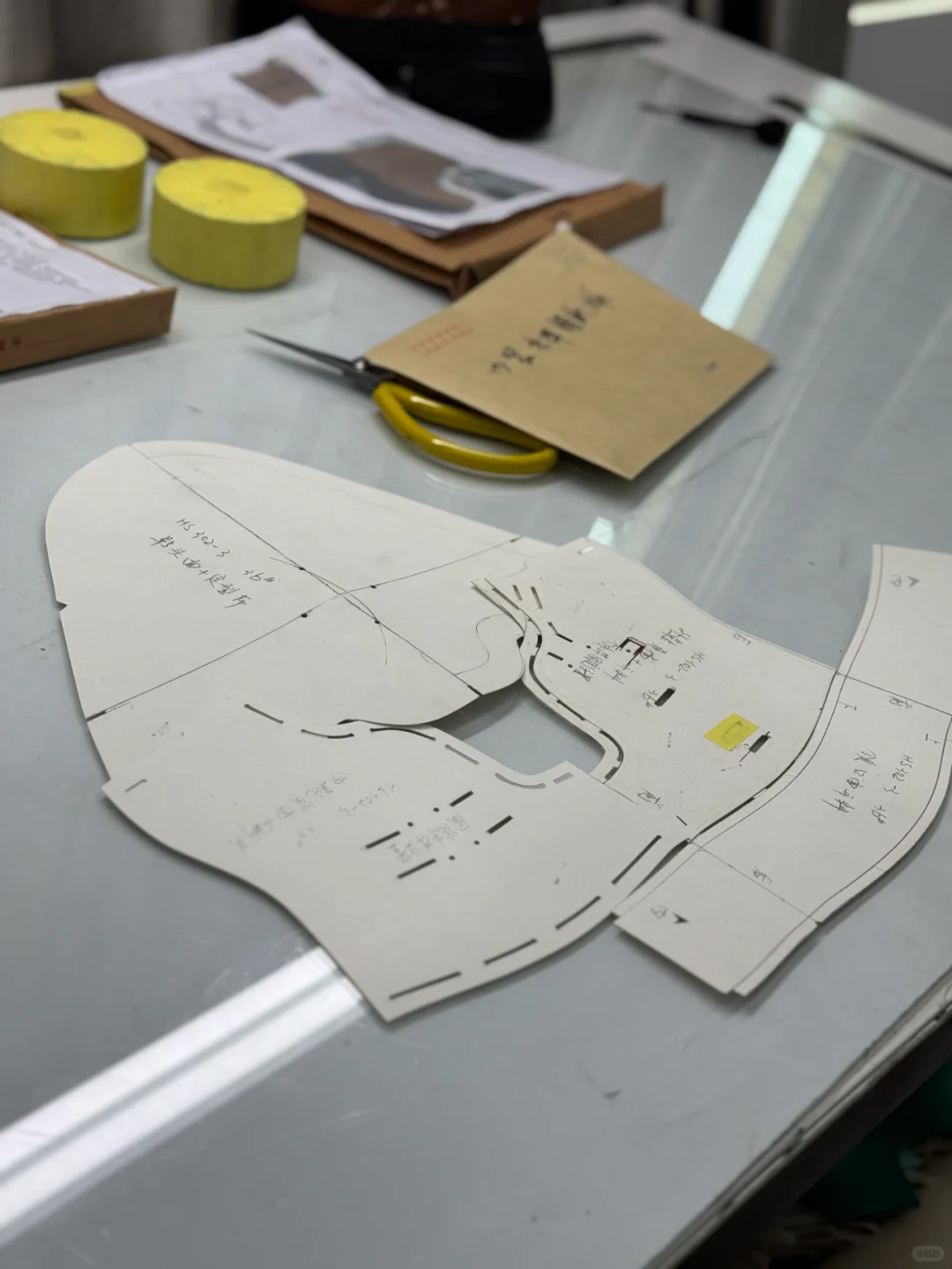

- 1.Pattern making: Based on design drawings or reference samples, pattern makers create precise cardboard patterns — the "templates" for subsequent cutting and sewing, which directly affect the accuracy of the shoe’s shape.

- 2.Cutting and initial sewing: Fabrics (such as leather or cloth) are cut according to the cardboard patterns, followed by initial sewing to make the first physical sample, transforming the design from 2D to 3D.

- 3.Sole matching: If using public mold soles, the factory can purchase them directly, taking very little time; if custom private mold soles are needed, it will take time to complete the mold making, which depends on the mold’s complexity.

- 4.Fitting and modification: After the initial sample is made, check if the overall effect meets the design expectations, then test the comfort and fit through trial wearing. If there are issues like rubbing or shape deviation, pattern makers will adjust details repeatedly until meeting the requirements.

- 5.Final confirmation: Once modified and approved, the sample is finalized. In our factory, relying on mature processes and experienced pattern makers, the sampling cycle for regular styles is usually 7-10 days.

II. Key Factors Affecting Sampling Time

Why does it take 3 days for some factories to make a sample, while others need 2 weeks? It mainly depends on the following factors:

- 1.Design complexity: Shoes with special structures (e.g., irregular toe caps, multi-layer stitching) or intricate craftsmanship (e.g., hand embroidery, 3D stitching) require more time to handle details, prolonging the process.

- 2.Material properties: Different materials vary in handling difficulty — for example, soft sheepskin needs careful cutting, while rigid PU requires equipment parameter adjustments, both affecting progress.

- 3.Pattern maker experience: Senior pattern makers can quickly predict issues (e.g., fabric stretch rate’s impact on shape) to reduce rework, while novices may need multiple trials, taking longer.

- 4.Communication efficiency: Close collaboration between designers and pattern makers is crucial. Clear design instructions and timely feedback avoid "mismatches between what’s made and what’s wanted," saving significant time.

- 5.Equipment and technology: Factories with advanced equipment like automatic cutting machines and 3D foot-testing instruments can improve pattern accuracy and fitting efficiency, shortening the sampling cycle.

III. Our Sampling Advantage: 7-10 Days for Efficient, Precise Samples

As a professional fashion shoe manufacturer and OEM women's shoes service provider, Guangzhou Happy Fashion International Trade Co.,LTD has specialized in mid-to-high-end footwear for years. Our sampling team has an average of over 10 years of experience, familiar with various materials (from genuine leather to eco-friendly fabrics) and styles (high heels, casual shoes, boots, etc.), enabling efficient handling of complex designs.

Whether for custom women's shoes or as a high heel shoes supplier, we ensure qualified samples within 7-10 days through clear process management and advanced equipment. For ODM orders, we support full-process services from design to sampling, turning your ideas into reality quickly.

From design drawings to mass-producible samples, every step tests a factory’s professionalism. If you’re looking for a reliable China shoe factory with efficient sampling and quality assurance, contact us — our OEM/ODM products have been sold in Saudi Arabia, Qatar, Dubai, Europe, America, and more. We adhere to "high-end, high-quality, high-efficiency" and look forward to becoming your trusted partner.