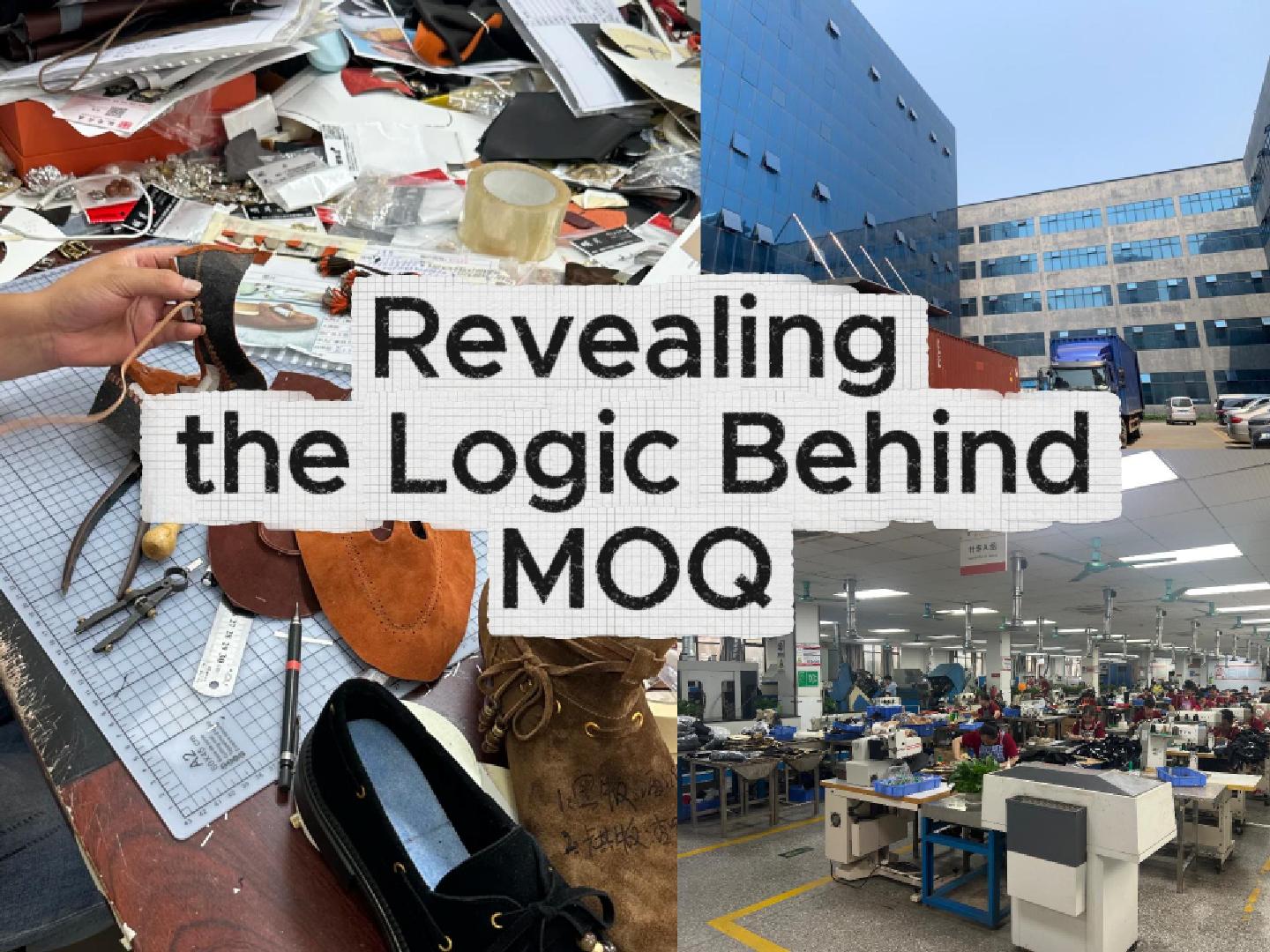

Why Do Shoe Factories Require High MOQs? A Complete Guide for Shoe Startups

Launching your own footwear line is exciting — until you hit the roadblock of MOQ (Minimum Order Quantity). Many designers and startup shoe brands approach factories with innovative sketches, only to be discouraged by a reply like:“Our minimum order is 3,000 pairs.”

Does that mean factories don’t care about small brands? Are they simply ignoring smaller clients? The truth is: it’s not about arrogance — it’s about cost.

The Real Reasons Behind High MOQ in Shoe Manufacturing

Shoe factories don’t set high order quantities to make life hard for new designers. Instead, it comes down to hard production costs and efficiency:

-

High Mold & Last Costs Every shoe requires a custom last (the 3D form) and cutting dies. Developing these tools can cost thousands of dollars. If a factory produces only 100 pairs, the tooling cost per pair would skyrocket — making the shoes nearly impossible to sell at a reasonable retail price.

-

Material Sourcing Limitations Leather suppliers and textile mills also impose their own MOQs. For small runs, it’s often impossible for a factory to purchase the exact material you want unless the order meets supplier requirements.

-

Production Line Efficiency A footwear production line involves setup, training, and adjustments. Stopping the line after a few hundred pairs means wasted time, low efficiency, and financial loss for the factory.

👉 In short: high MOQ helps factories spread out costs, maintain efficiency, and stay profitable.

How Small Shoe Brands Can Overcome the MOQ Barrier

The good news? You don’t have to give up. There are practical ways for new shoe brands to start small while staying competitive:

✅ Look for “Small-Batch” or “Quick Response” Shoe Manufacturers Some modern factories specialize in small orders (100–500 pairs) with more flexible setups.

✅ Use Existing Shoe Lasts (Open Molds) Instead of developing new lasts, use a factory’s existing mold library and customize the upper design. This dramatically reduces cost and MOQ.

✅ Be Ready to Pay a Premium for Small Runs Small orders naturally have higher costs per pair. By showing flexibility and willingness to pay a fair premium, you’ll attract more factory partners.

How Our Shoe Factory Supports Small-Batch Shoe Brands

As a women’s shoe manufacturer with 20+ years of OEM/ODM experience, we deeply understand the struggles of startups and independent designers. That’s why we’ve built our production model to support small orders without compromising quality:

-

Flexible MOQ: We offer lower-than-industry-standard MOQs to help designers launch collections without being blocked by high volumes.

-

Extensive Last Library: With thousands of existing shoe lasts, we make it possible to customize designs while avoiding high tooling costs.

-

Small-Batch Expertise: Our multi-line production system is optimized to handle small orders efficiently, ensuring cost control and consistent quality.

-

One-Stop Development Support: From design consultation and material sourcing to production follow-up, we provide full-service guidance for startups.

Final Thoughts

If you’ve ever been discouraged by high MOQ requirements, remember: it’s not a factory “rule” to reject small brands — it’s simply the reality of shoemaking economics.

With the right strategy, you can start small, scale smart, and bring your creative footwear ideas to life.

👉 Ready to launch your shoe brand with small-batch production? Contact us today to discuss your project.